Outer-layer vertical blades

Disrupt regeneration mechanism of hairpin vortices→Drag reduction

Basic Research (Prof. Kwing-So Choi) : max. 25% local drag reduction

Applicability test : How large global drag reduction ?

Towing tank : max. 2.25%, Circulating water channel : max. 4.54%

Compliant Coating : Biomimetics (Dolphin’s skin)

Turbulent pressure → Surface deformation → Attenuation of Reynolds stress → Skin friction reduction (~7%)

Optimization of dynamic viscoelastic properties

Tuning to the frequency & wavelength of turbulent pressure field

5% drag reduction : further improvement expected

공기윤활기법 : Modular Carrier

Energy saving by air lubrication : visualization of air film → optimization of air injection

C-17st-5mm / Net Saving : -7.44%

C-17-13st-5mm(1-9)) / Net Saving : 33.87%

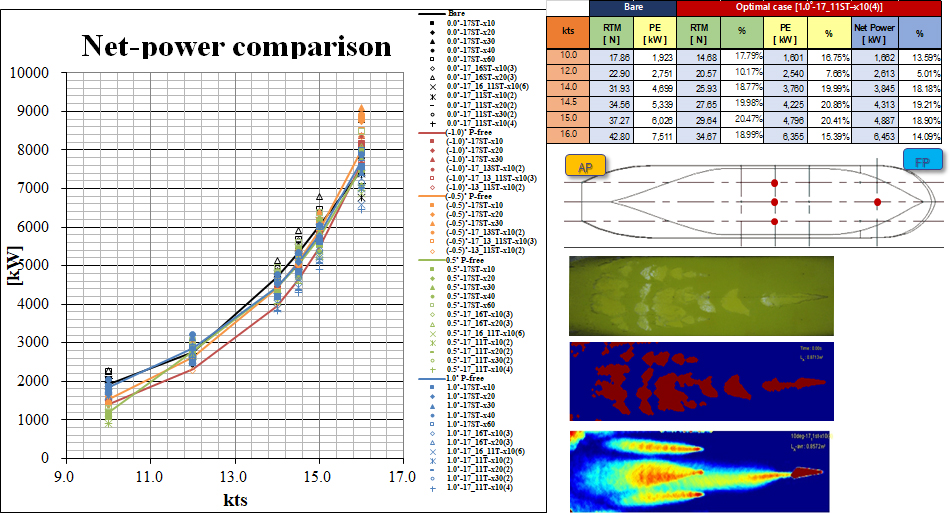

공기윤활기법 : 66k Bulk Carrier

Flat bottom area : 42.21% (WSA)

공기분사유량 최소화 → 에너지 저감효과 극대화

Optimal case : 19.2% net energy saving (pumping power = 1.65% of NCR)

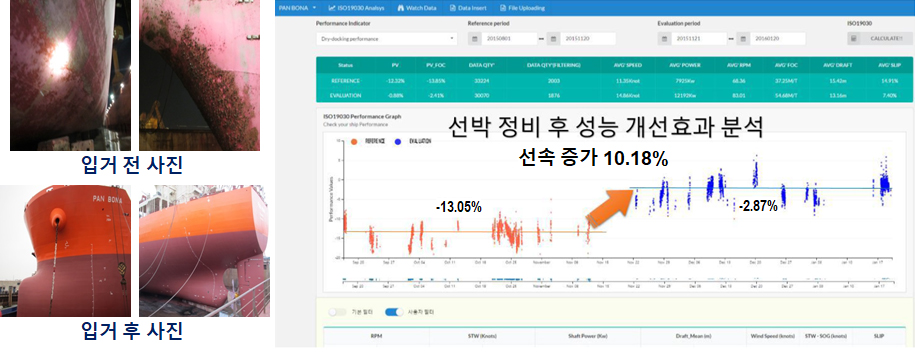

저마찰 선박 방오도료

마찰저항 저감 고분자 신소재 (FDR-SPC) 세계 최초 합성 (공동개발 박현 교수) : 마찰저항저감율 13.5% 달성 (매끈한 표면 대비)

FDR-SPC 기반 저마찰 선박 방오도료 개발 : 마찰저항저감율 25.4% 달성 (기존 선박도료 대비)

저마찰 선박 방오도료 실선 적용 : Capesize bulk 선 (‘15.12)

장기간 마찰저항 성능 : 6개월

실선 적용성 (방오성능) 검증 : immersion panel & patch test

실선 운항성능 ISO19030 기반 평가 : 선속 증가 10.2%, DFOC (연료소모량) 저감 48.06%

| 입거 전 (8개월) | 입거 후 (8개월) | ||||||

|---|---|---|---|---|---|---|---|

| Speed | DFOC | Speed | DFOC | ||||

| Ballast | Laden | Ballast | Laden | Ballast | Laden | Ballast | Laden |

| -14.96% | -13.05% | 81.21% | 58.16% | -6.65% | -2.87% | 28.53% | 10.10% |

선박저항성능연구실

선박저항성능연구실